Automation Solutions

Bobbin legs with the Digital Automation System, encoder attached to each leg and Automation boards attached to each group, the quantity consumption values of each active bobbin, how many kg is used for which combination, the return of the bobbins to the warehouse over the remaining quantities, the required cross-checks of the consumed bobbins and the produced combinations. Their costs are made dynamically on the paper they are used one-to-one.

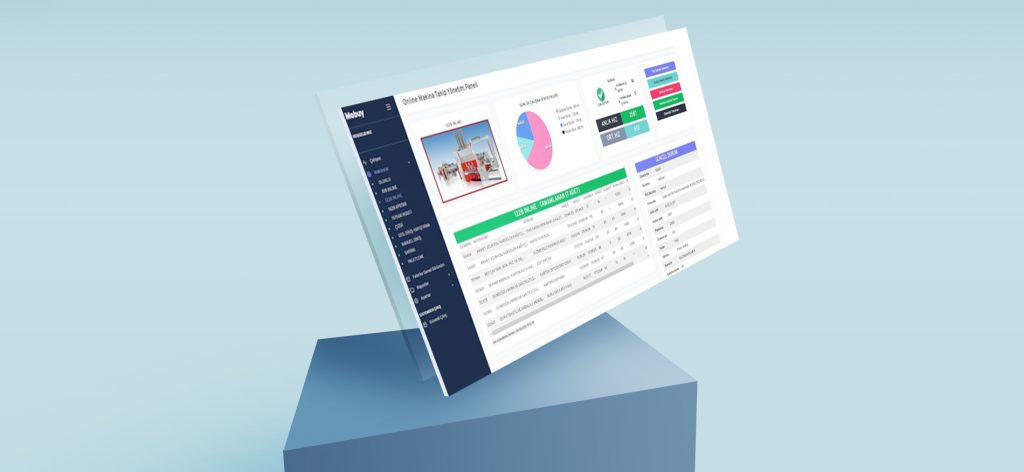

Combined information planned in the Winproject program is instantly sent to the corrugated machine with the integration of the Corrugated order change software, in the order determined on the combined planning screen.

The aim of the project is to send fully automatic combined data to the units, as well as to automatically receive the actual production information of the sent data from the machine. Thanks to this business intelligence module working with a double interface, user errors are minimized, and instant and accurate data recording is provided.

Thanks to data collection automation as BSS

- Collecting production data

- Preventing the machine from running without selecting the relevant planned order

- To determine the malfunctions arising in production

- To determine production efficiency based on machine and personnel,

- To determine the time occupied by the order-based production on the machines, and thus to meet the deadlines of new orders.

to ensure that the deadlines are given correctly, - Analyzing the Stop and Fire Reasons and presenting this as a report,

- In case the machines stop for too long unnecessarily, notify the relevant unit or persons via SMS.

to ensure that, - Drawing the graph of the order during production and thus creating a visual production perception,

- Seeing the jobs behind the Machines remotely using Mobile Phones, Tablets or Computers,

To get the list of orders produced, to learn instant machine production and when they will be finished,

We do operations such as monitoring the performance graph. - Thanks to all these, even if you are not at your workplace, you can control the production processes

as if you were at work.

With our electronic panels to be mounted on cardboard and paper sizing machines, these machines are also It becomes fully integrated with ERP.

The bobbins that are dimensioned can be measured in quantities thanks to their barcode structures.control and traceability.

The system is used for the return of the unfinished bobbins to the warehouse.

The remaining kg information and warehouse returns are recorded by the company.